Wheel Inspection Center WIC-UG

Uniformity measurements and geometry measurements of car wheels

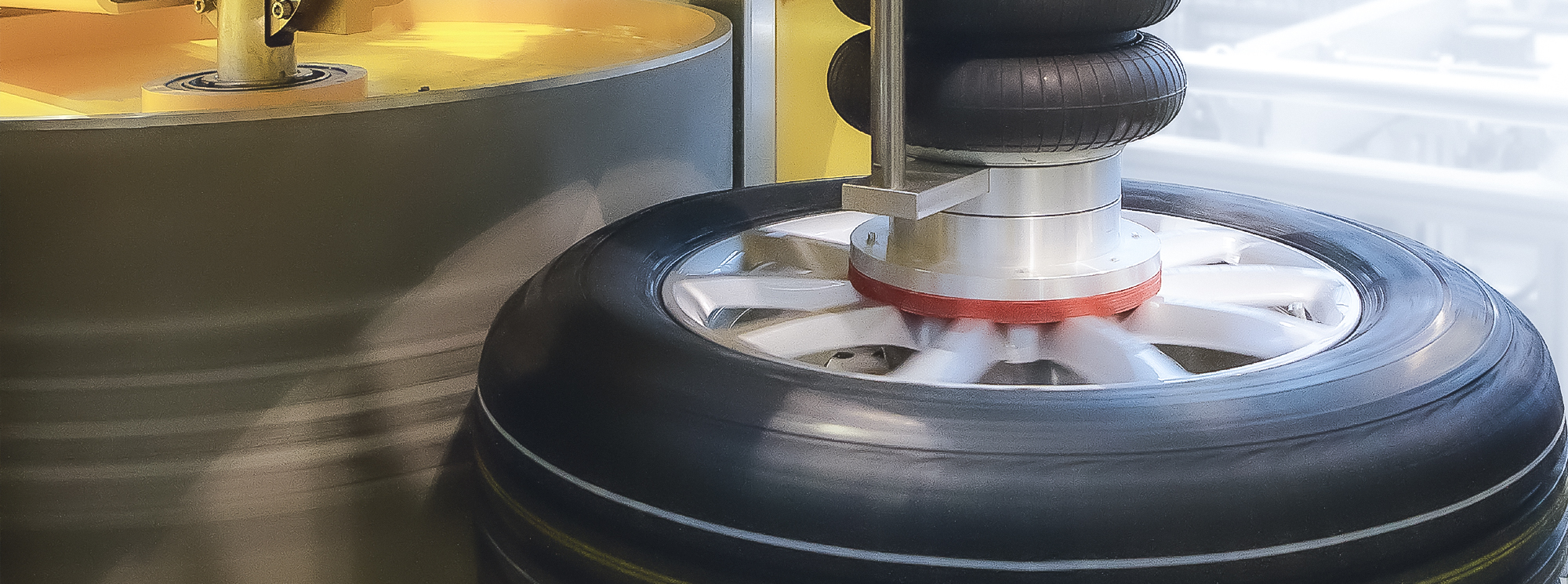

Our Wheel Inspection Center (WIC-UG) is a recognized machine in the global wheel industry. In the wheel industry, production lines are designed for maximum efficiency. The availability of each individual machine in the assembly process is particularly important here. We designed the WIC for this requirement. Our WIC is based on a spindle design that has been tried and tested in the tire industry.

We configure our WICs as WIC-U (uniformity) or WIC-UG (uniformity + geometry) according to customer requirements.

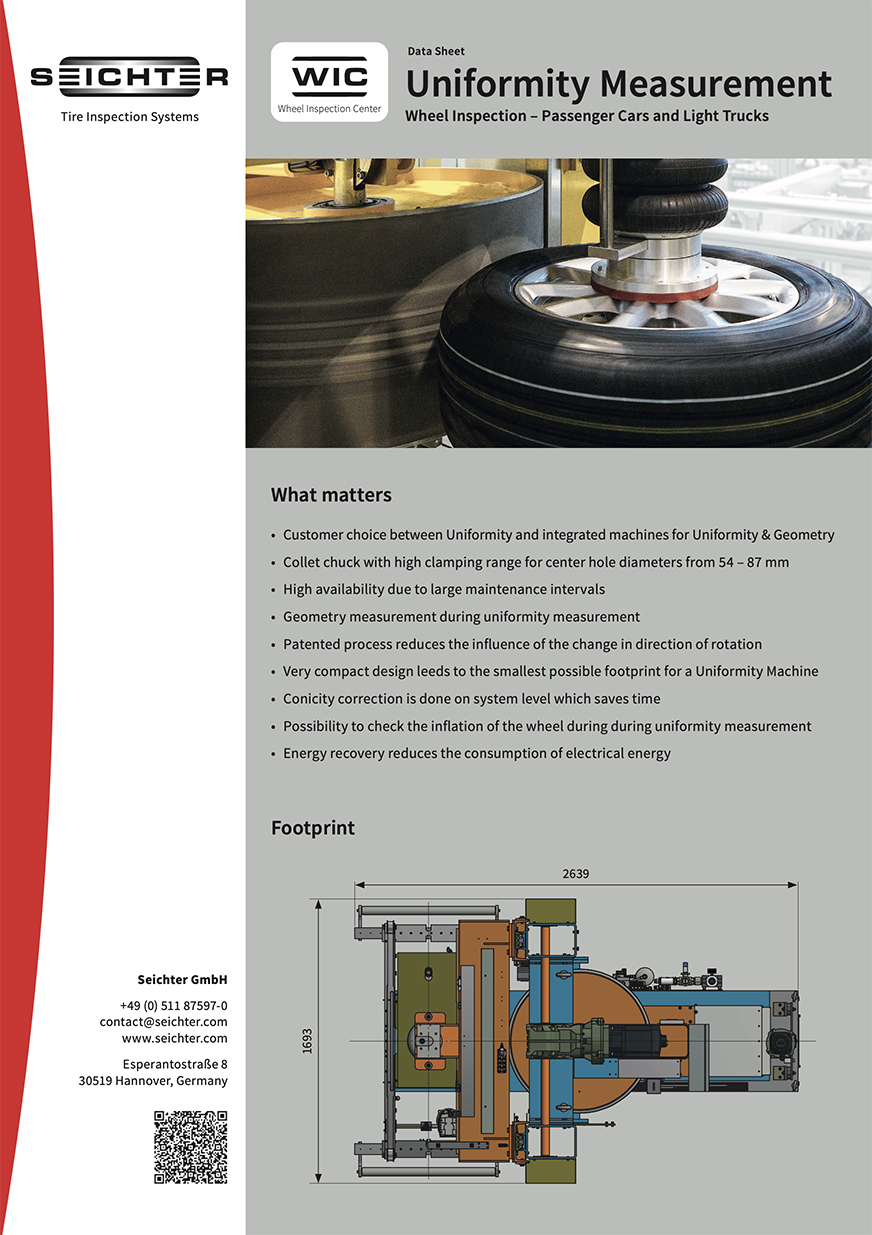

What matters: Features of the Seichter wheel machine

- Customer choice between Uniformity and integrated machines for Uniformity & Geometry

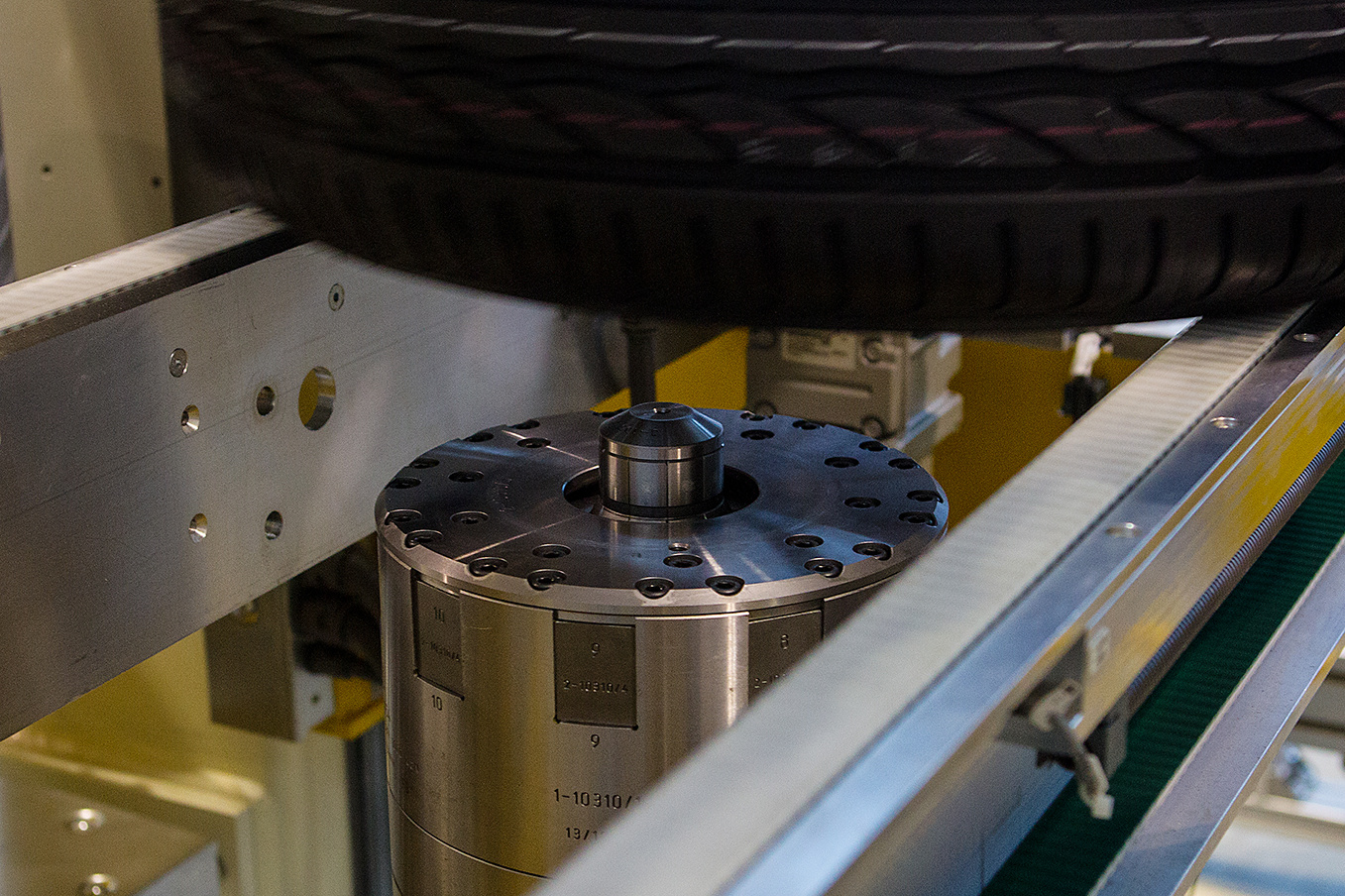

- Collet chuck with high clamping range for center hole diameters from 54 – 87 mm

- High availability due to large maintenance intervals

- Geometry measurement during uniformity measurement

- Patented process reduces the influence of the change in direction of rotation

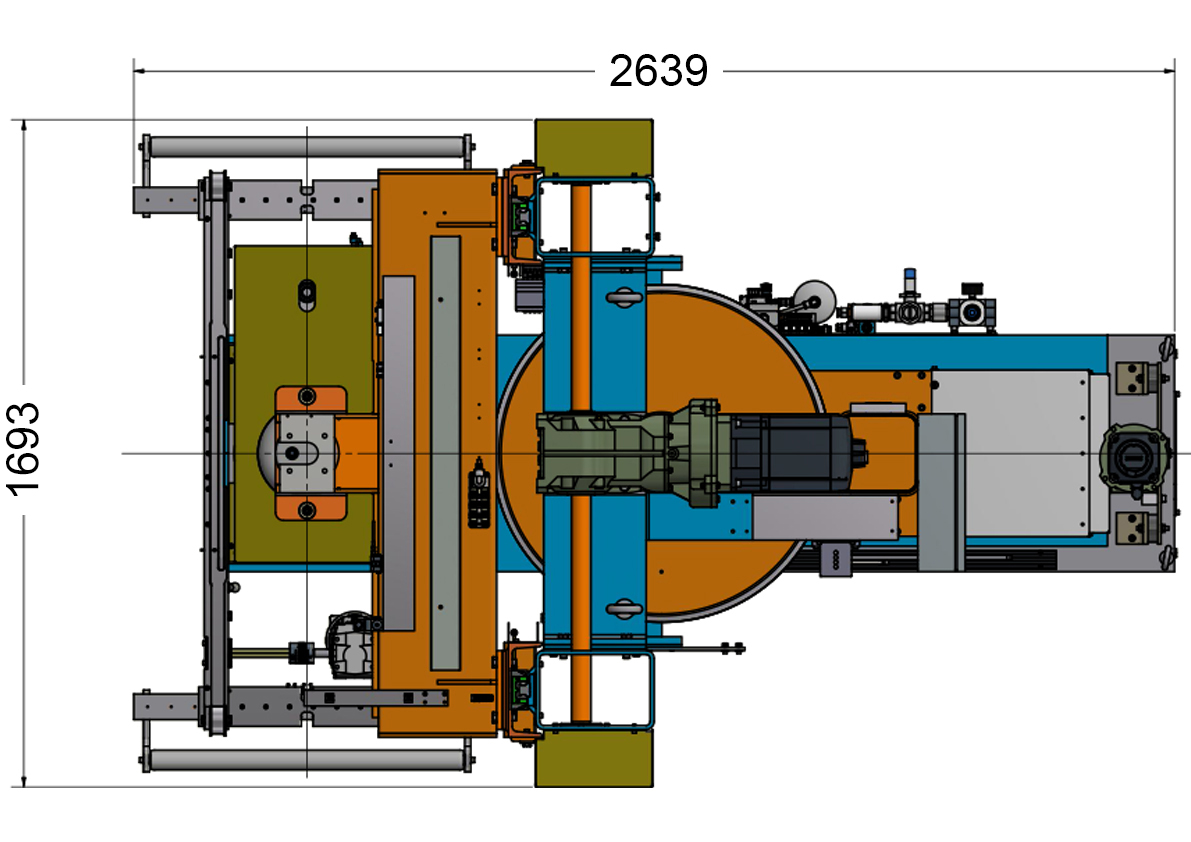

- Very compact design leeds to the smallest possible footprint for a Uniformity Machine

- Conicity correction is done on system level which saves time

- Possibility to check the inflation of the wheel during uniformity measurement

- Energy recovery reduces the consumption of electrical energy

To enable the chucking of a wide range of rims with a Wheel Inspection Center without having to change the chuck, we use a chuck with a large stroke that nevertheless meets the high requirements for their radial runout.

The fold-away conveyor makes it so much easier to access the machines for maintenance.

The recognized compact size of Seichter TICs is also a hallmark of the Seichter WIC. Ease of maintenance is always another important factor here, because it reduces downtimes and keeps the availability of the system at a high level.