Precision – Speed – Durability

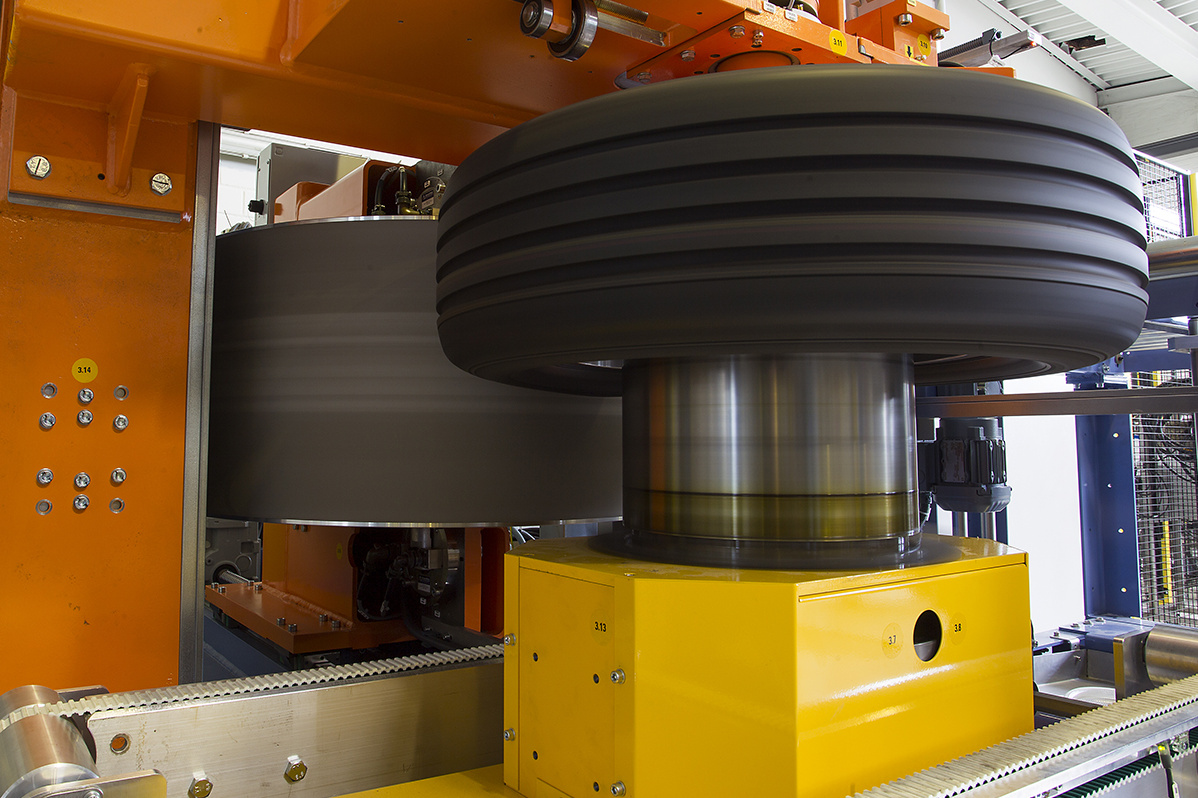

Each product follows a clear target corridor starting right in its development phase. Among many other attributes, we at Seichter place the precision, performance and durability of our machines at the center of our product development.

This means that the quality of our measurement technology is not a goal, but rather the result of careful work.

Generating measured values is easy, whereas deriving valid measurement results from them is not.

Our assets are in a deep understanding of the physics of tires and sophisticated mathematical models. In the harsh production environment, however, the only measurement results of any value are those that are reproducible. This requires a resilient machine, sturdy measurement technology and minimal wear.

A solid test speeds up assembly at the customer’s premises

Before delivery, every Seichter machine for final finishing of tires is tested extensively in our modern assembly hall. This ensures that commissioning at our customers’ premises is completed within two weeks.

Precision is our trade.

Tolerances in the single-digit µ range must be strictly adhered to.

We are well used to managing the challenging specifications of our customers.