Tire diameters are getting bigger and bigger, requiring bigger and heavier measuring rims

Even if the rims are changed less and less frequently during final finish, it is not possible to completely do without a conversion of the measuring rims on the balancer or uniformity machine.

As weights increase, the work of assembling, disassembling and transferring the rims to a warehouse becomes more arduous. In addition to that, the valuable rims can be damaged during transport or storage and the operator needs time to transfer the rims to the warehouse.

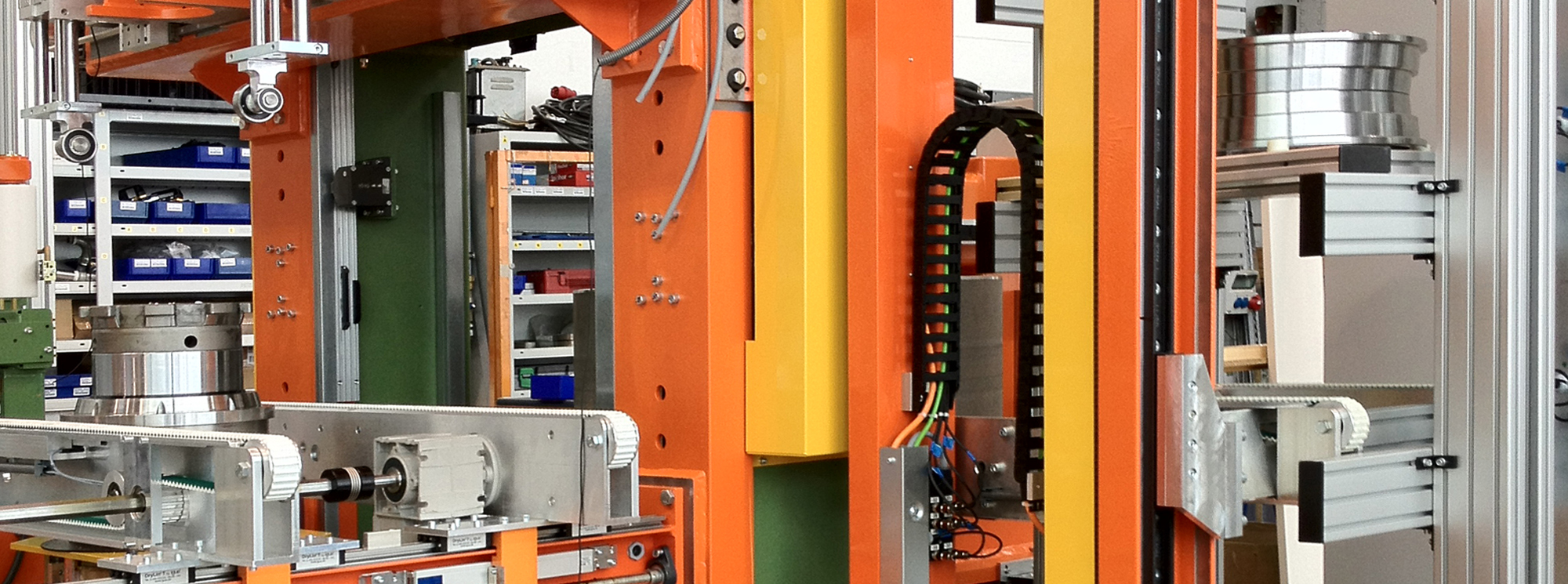

To meet these requirements, Seichter has developed an efficient and compact rim change assistant. Space-saving storage of the rims right beside the machine makes handling easier, saves changing time, increases work safety and makes it easier for the operator to change rims over the long term.

The transfer of the rims itself takes less than 3 minutes.

Ergonomics and work safety for the user are improved over the long term because there is no need whatsoever to lift or transport the rims.

The rims are fixed into place by the user.

Seichter looked for a compromise between the degree of automation and the cost-effectiveness of the tried-and-tested rim change assistant.

On the main axis, the changing machine moves to the rim rack and sets down the pair of rims automatically. Another pair of rims is then removed.

Perpendicular to the main axis, the belt conveyor then transports the pair of rims onto the desk in the TIC-UG.