Upgrade of the sensor system and complete retrofits

Given the long service lives of our testing machines, it often makes good economic sense to upgrade the testing technology rather than replace the machine as a whole. The modular design of our sensor system – physically separated from the machine base – allows the Seichter measuring system to be modernized on almost all uniformity machines on the market. And our sensor system is of course also suitable for modernizing outdated sensors on measuring machines from other manufacturers.

First Generation: Geometry system with capacitive sensors

The DMU (Distance Measuring Unit) is an invention of ours that revolutionized the tire market. Its capacitive sensors scanned the tire and provided measurement results that completely reshaped the best available technology of the time.

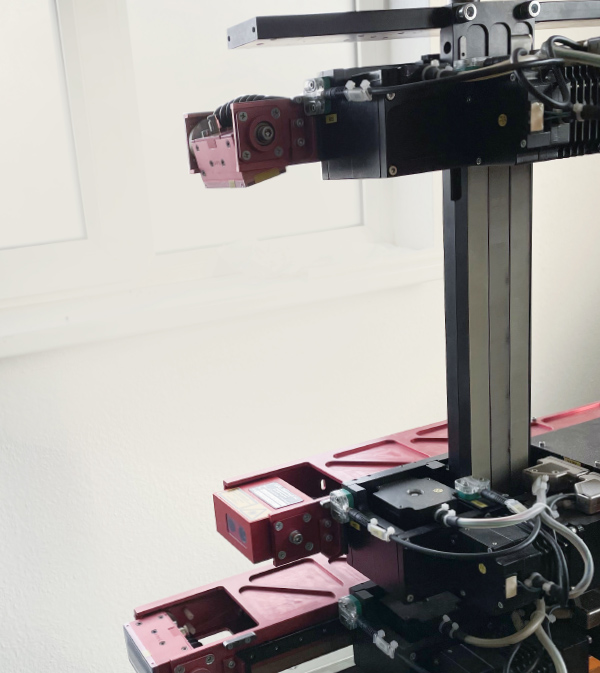

Second Generation: Geometry system line laser and 2D camera

The SMU (Sheet-of-Light Measuring Unit) with a line laser is the best technology available today and is based on the principle of triangulation.

Upgrades in testing technology

For preventive maintenance, existing information is linked to additional sensors. This avoids as much unplanned downtime as possible and reduces costs.

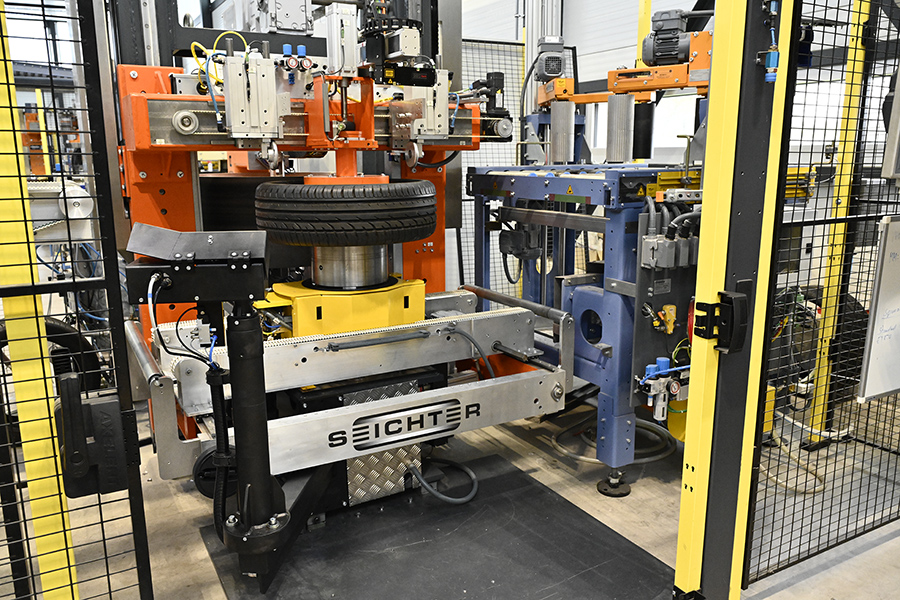

Retrofit including installation of the Seichter geometry system

In the early years of digital tire testing technology, well-known manufacturers of testing machines used Seichter sensors. Our sensors have been both installed in new machines and also retrofitted into existing machines worldwide. We review full retrofits of testing machines on request.