GEOtwin

Digital Twins enable the creation of virtual models of physical products or systems. They not only provide insights into the quality of products and processes, but also create a basis for product optimization and continuous innovation.

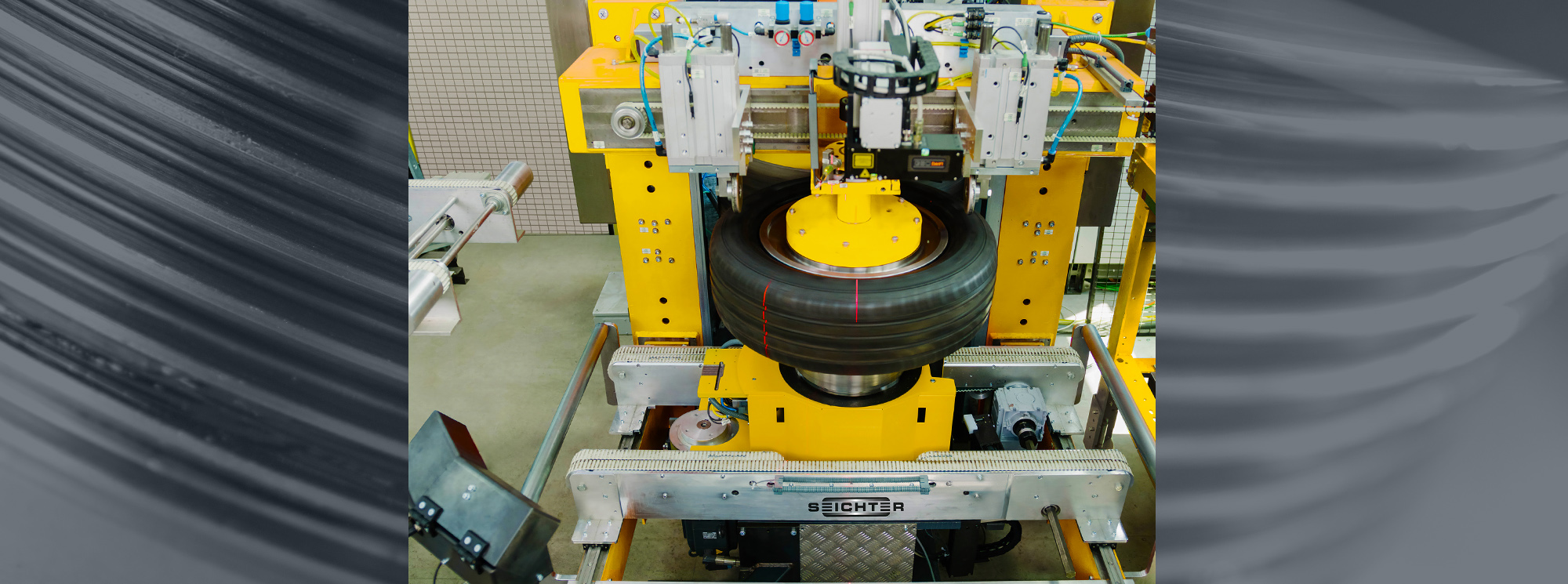

The new GEOtwin represents the third generation of measuring systems for measuring the geometry of tires. The core of the innovation is the creation of a Digital Twin of the surface of the tire to be measured. The calculation of a virtual tire is based on high-speed 3D sensors and an intelligent software solution from Seichter.

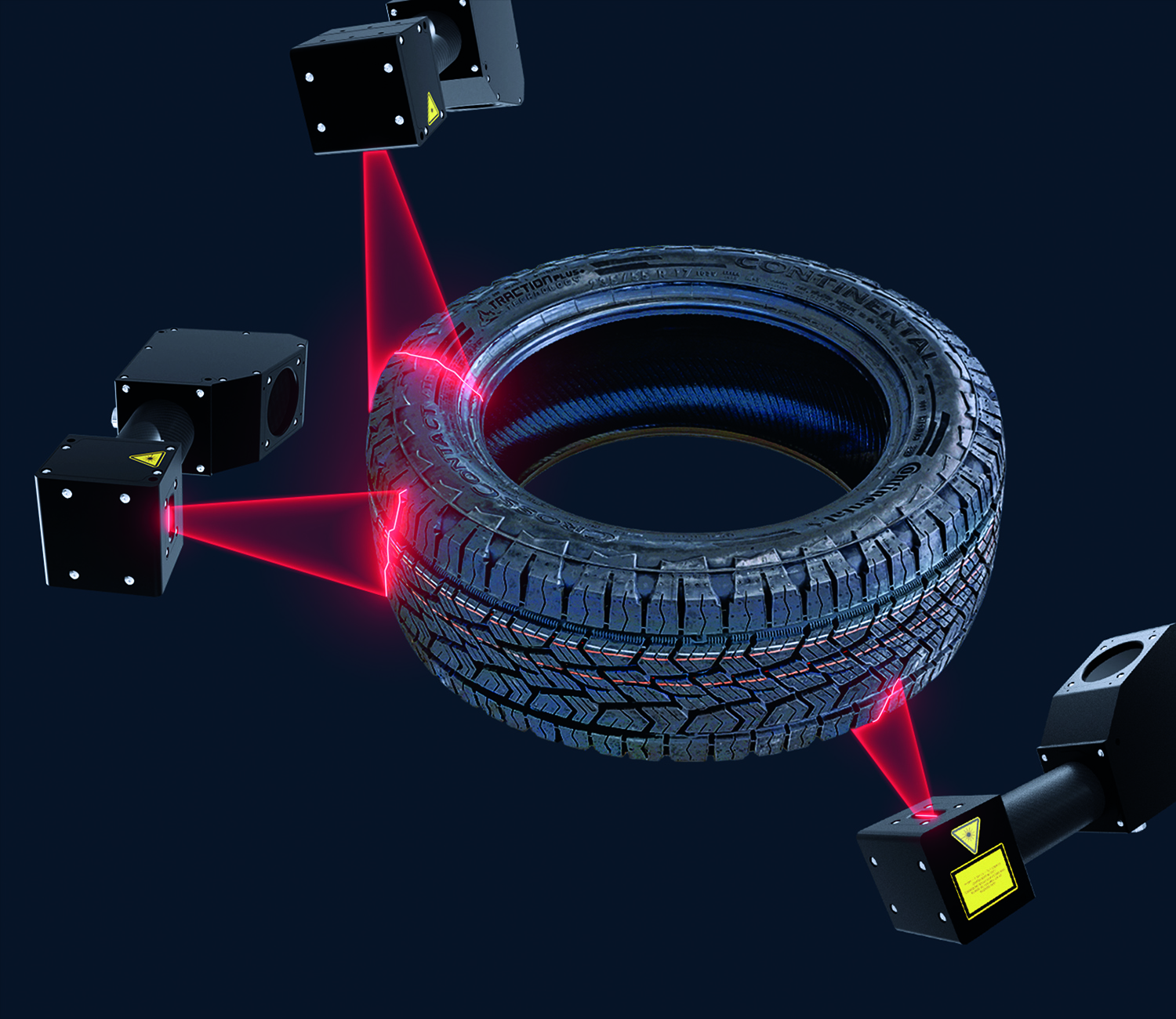

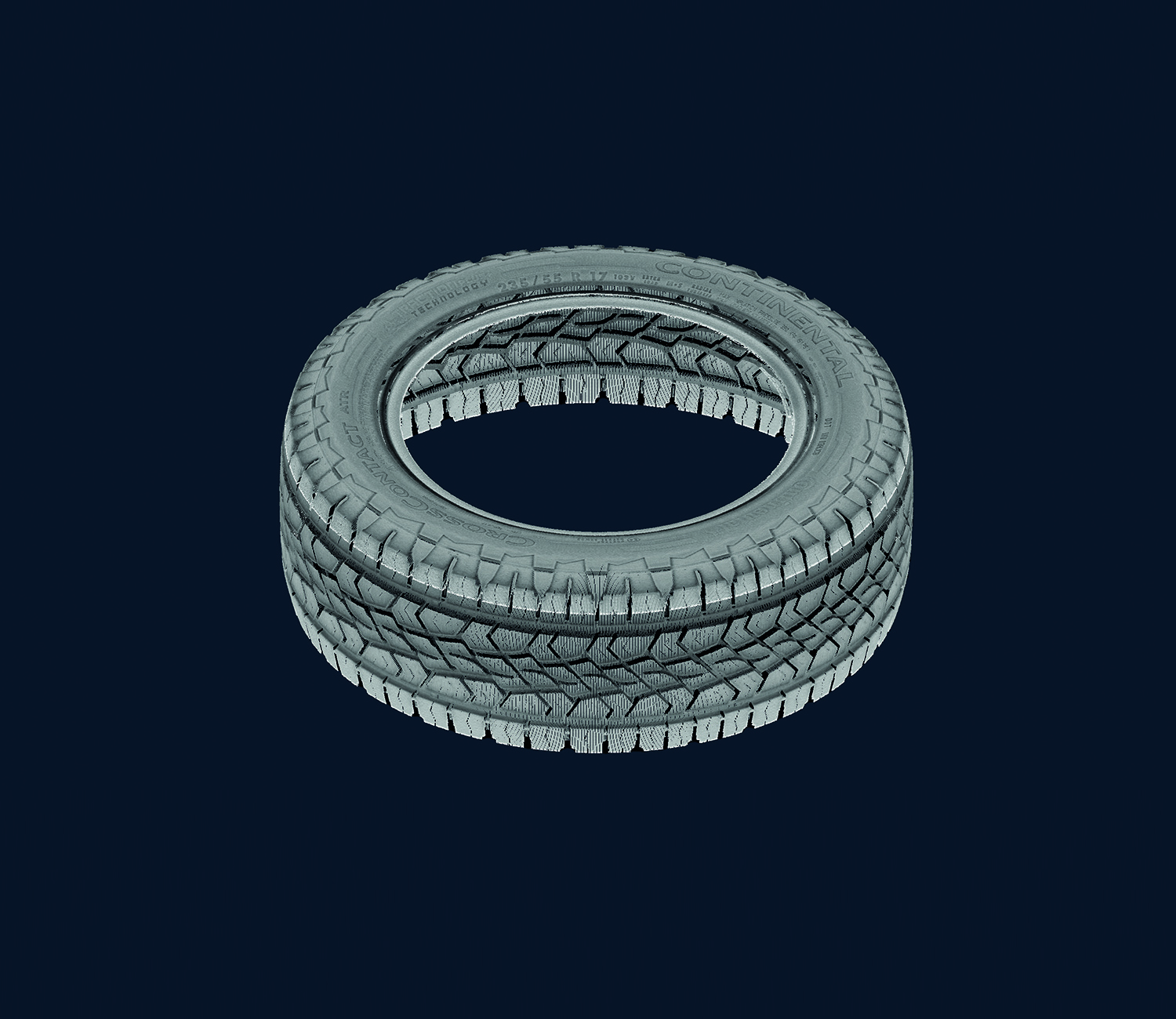

In the first step, a Digital Twin is generated for each tire.

High-speed 3D sensors are independently integrated into the machine and scan the tire from different positions. There are currently three sensors in use. The two sidewall sensors can only be moved radially in order to be able to follow the tire diameter and optimally align the measuring field. We therefore do not accept any compromises in terms of image quality with GEOtwin. The tread sensor is not movable. Each sensor creates its own point cloud, which is then combined to form a common point cloud.

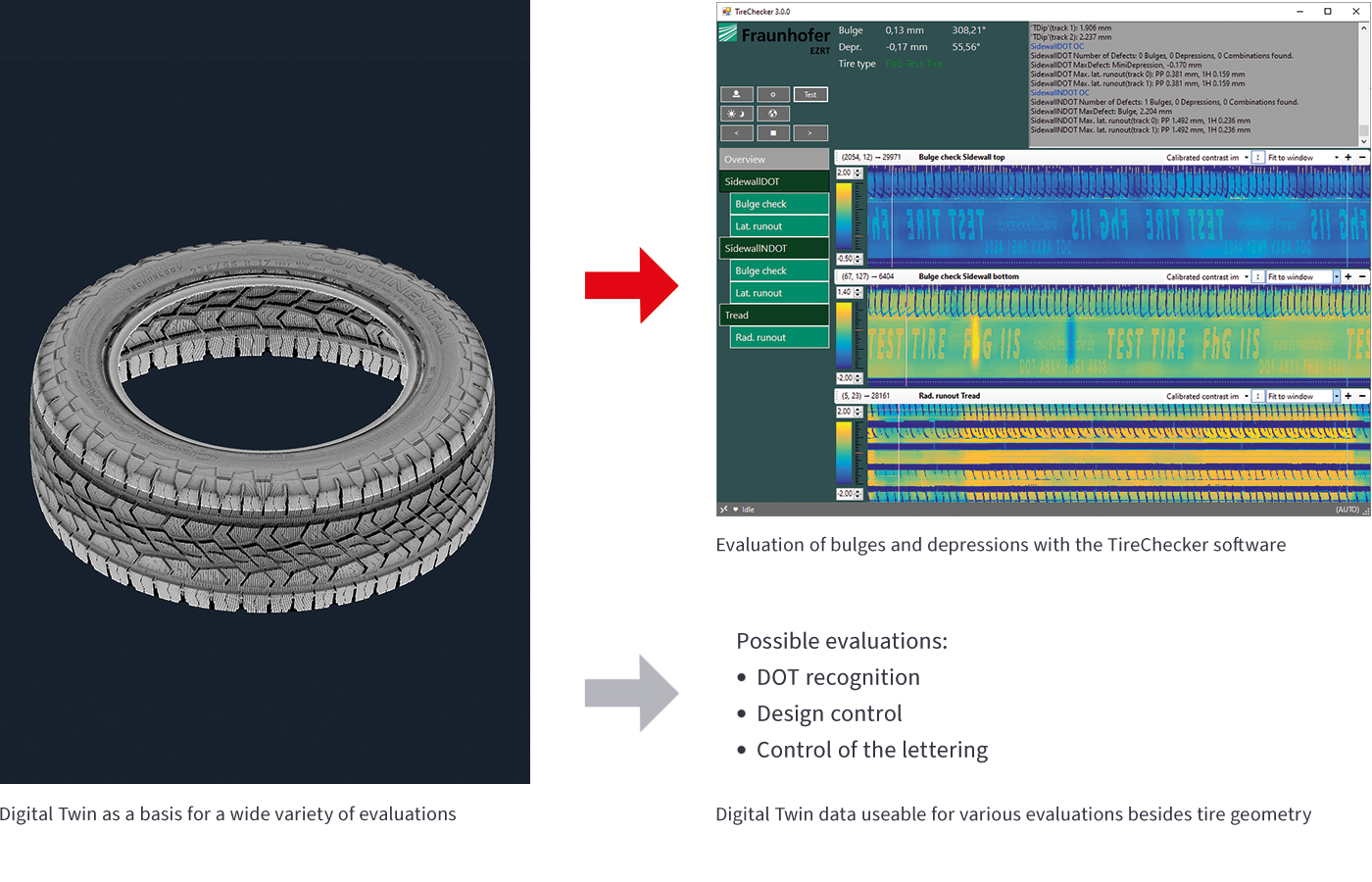

In the second step, the image is evaluated based on the Digital Twin.

Seichter's GEOtwin makes the Digital Twin data available for the following evaluations. The classic analysis of bulges and depressions is carried out using the well-known TireChecker from Fraunhofer. The three tracks are clearly shown in one mask.

It is important that the images for the evaluating system no longer depend on the measurement situation. This means that the evaluations can be repeated or modified at different times. In addition, the image transferred to the TireChecker always has the same height resolution and format. This means that only the evaluation is configured in TireChecker and all customer systems can be parameterized in the same way.

Technical Data

| Harmonics: | 1-31 |

| Profiles/rev: | 2.048 |

| Pixel on the tread: | 1.024 |

| Pixel on the sidewall: | 512 |

| Line length – sidewall: | 100 mm |

| Line length - tread: | 400 mm |

| Laser class: | 3R |

| Travel distance sidewall sensors: | 150 mm |

| Measurable tire dimensions: | see datasheet Uniformity |

Fundamental Advantages of the GEOtwin System

- Geometry measurement does not affect the cycle time of the machine

- Only two driven axles

- Time saved when setting up new articles by eliminating the need for teaching

- Saved 3D image (Digital Twin), can be measured again after any time

- Area behind the rim flange partially visible due to the sensors being positioned at an angle

- Outstanding height resolution

- Minimized shading due to small triangulation angle

- Sensor replacement does not require new calibration

- A safe distance between the sensors and the tire avoids the risk of collision

- Lean, energy efficient linear cylinders for the radial movement of the sidewall sensors

- All sensors protected from contamination by a folding housing

- Easy to retrofit as the sensors are arranged independently