Without lube, there can be no clean measuring process

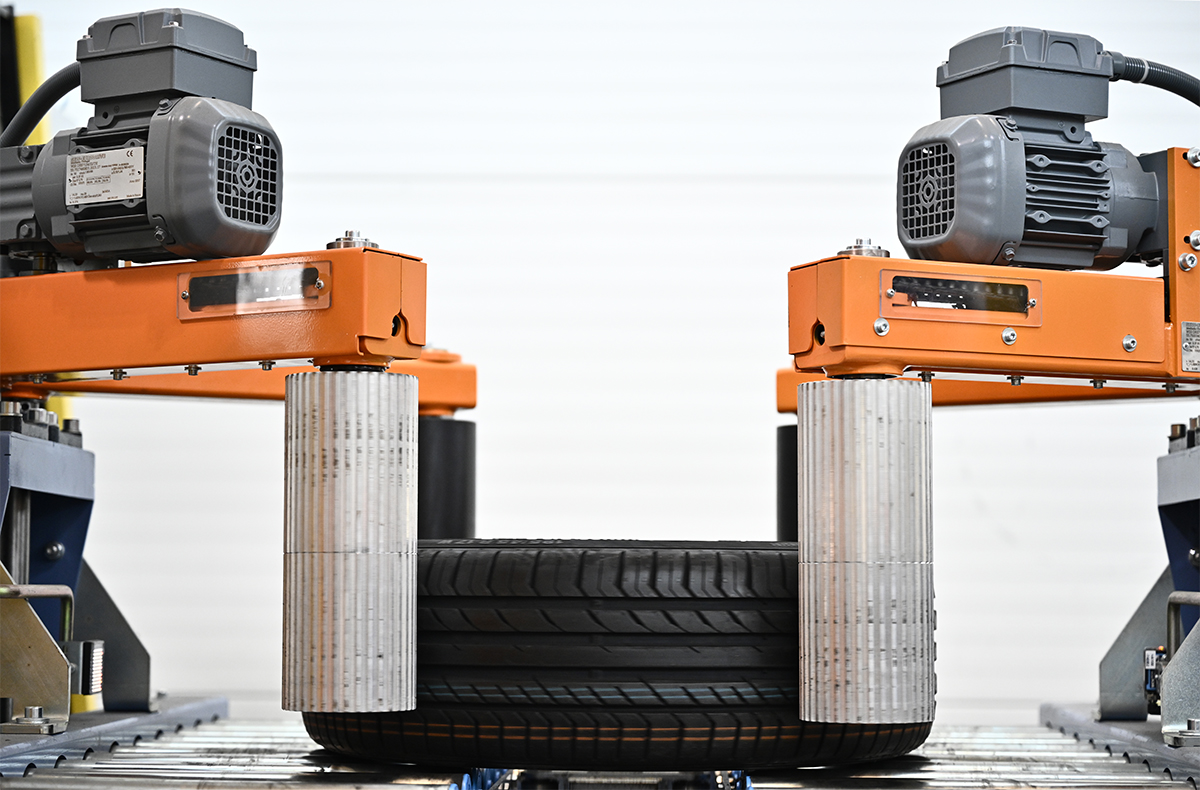

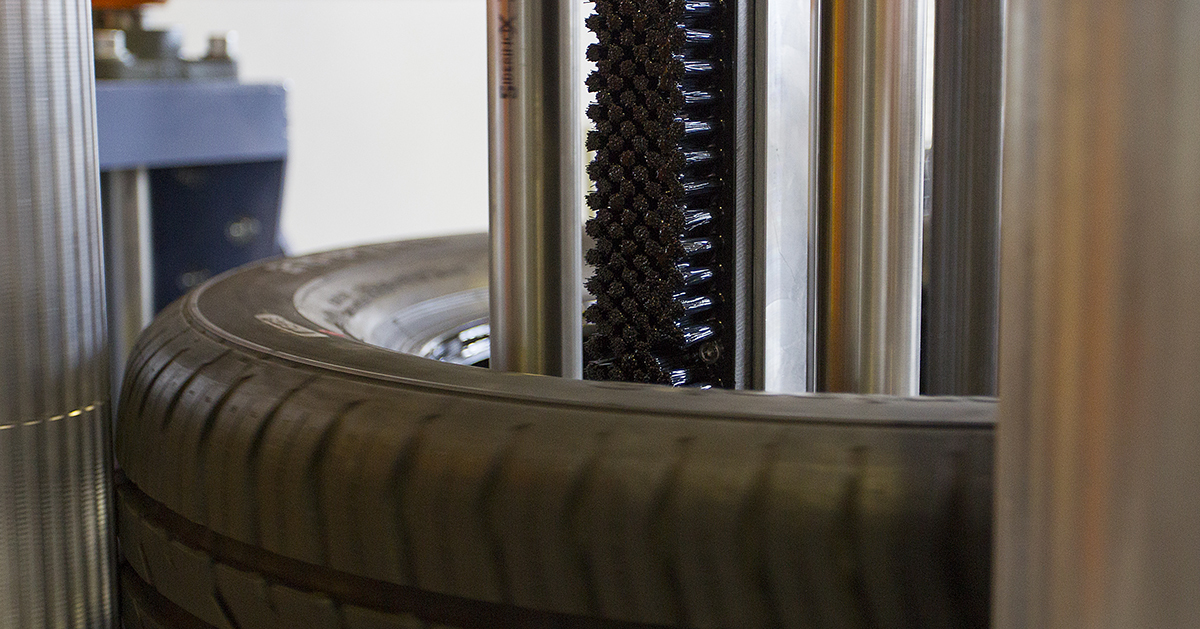

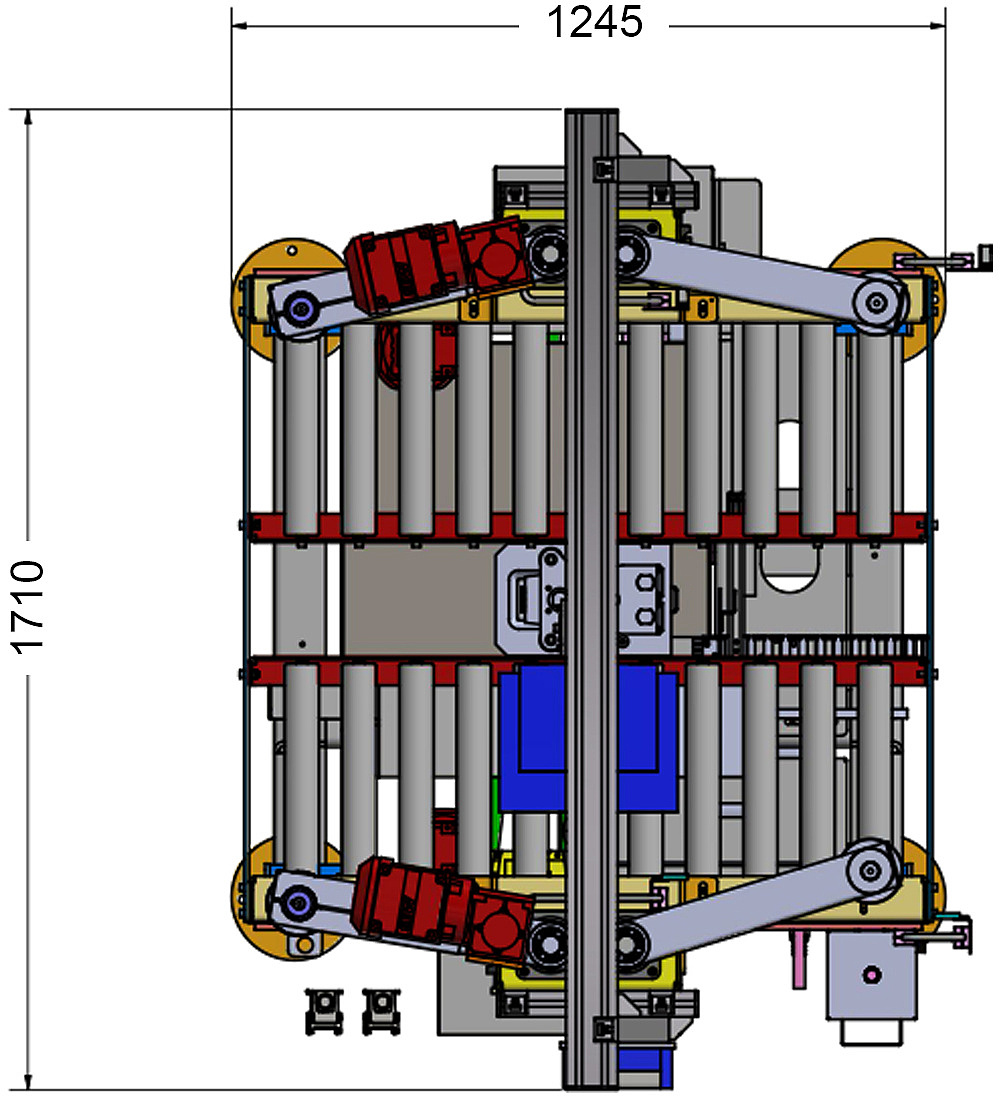

The lube station has two basic functions that are crucial for the subsequent measurement of the tire. First, the tire bead is evenly moistened with a special lube solution. This ensures that the tire fits perfectly on the measuring rims. Second, the tire is precisely centered to ensure precise positioning in the measuring station.

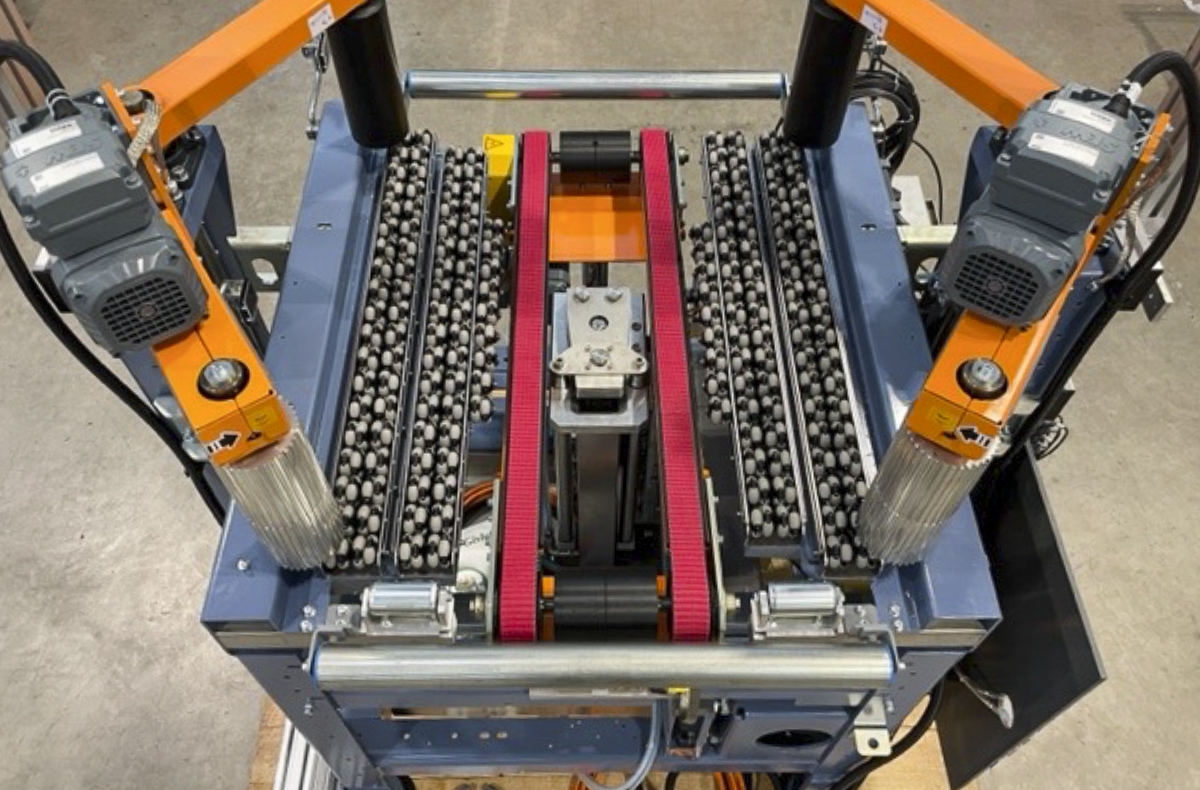

Two different conveying concepts available. Customers do have the choice between classical rollers and a belt conveyor with Omni-rollers.

Advantage

- conveying without pneumatics

- less different spare parts

- robust

Concession

- wear of the drive chain an the gears

- maintenance of the driven parts

- noise level

- friction between tire/rollers during centering and spotting

Advantage

- centering and spotting process with less friction on the tire shoulder, especially in case of big and heavy tires

- almost free of maintenance

- less noisy

Concession

- durability of the omni-rollers might be an issue

- broken omni-rollers can damage the tires

- belt unit needs compressed air